WebLytics brings remote monitoring, device diagnostics, and data analytics capabilities to OnRobot’s line of collaborative application-focused hardware solutions.

WebLytics可为OnRobot一系列聚焦于协作式应用的硬件解决方案赋予远程监控、设备诊断和数据分析功能

Odense, Denmark, November 11 2021: OnRobot, the One Stop Shop for collaborative robot applications, makes its software debut with the launch of WebLytics, a unique production monitoring, device diagnostics, and data analytics solution designed to enhance productivity and minimize downtime.

丹麦欧登塞,2021年11月11日:协作式机器人应用一站式应用供应商OnRobot宣布推出首款软件产品WebLytics。该软件提供了独特的生产监控、设备诊断和数据分析解决方案,可提高生产力并最大化减少停机时间。

Capable of monitoring the performance of multiple collaborative applications simultaneously and in real-time, WebLytics gathers equipment data from both robots and tools and transforms it into easy-to-understand, visualized device and application-level intelligence.

WebLytics能够同时实时监测多个协作式应用的运行性能情况,并从机器人和工具中收集设备数据,再将其转化至易于理解的可视化装置及智能应用呈现。

“The launch of WebLytics is an important landmark for OnRobot, our customers, and our global integrator network,” says Enrico Krog Iversen, CEO of OnRobot. “WebLytics is the first software solution to provide real-time, application-focused data for collaborative applications across major robot brands. As our first software product, WebLytics marks the beginning of OnRobot’s journey into robot software and completes our vision of providing a One Stop Shop for collaborative applications on both the hardware and software side.”

“WebLytics的推出对OnRobot自身、我们的客户以及我们全球的集成商网络而言,都是一个重要的里程碑。” OnRobot首席执行官Enrico Krog Iversen表示,“WebLytics是首个可为各大主要机器人厂商的协作式应用,提供实时、以应用为中心数据的软件解决方案。作为OnRobot的第一款软件产品,WebLytics标志着OnRobot已涉足机器人软件领域,达成了我们在硬件和软件方面为协作式应用提供一站式服务的愿景。”

For end users and integrators, WebLytics not only eliminates manual data collection — it provides actionable insights into how well a collaborative application is performing, offering live device diagnostics, alerts and preventive maintenance measures to keep costly robot cell downtime to a minimum.

对终端用户和集成商而言,WebLytics不仅可以帮助他们告别手动收集数据,还能提供深层、实用的信息,反映协作应用的实时运行性能状况,同时也提供实时设备诊断、警报和预防性维护方法,从而最大化减少成本高昂的机器人停机时间。

“Improving efficiency while controlling costs matters to Chinese local manufacturers. This efficiency management tool WebLytics will help to drive the application of collaborative automation in China.” says Felix Wang, Country Manager of Greater China at OnRobot.

OnRobot大中华区总经理王峰表示:“提升效率和控制成本是中国本土制造商关注的重点。适用于协作式应用的效率管理工具WebLytics的推出,将大大推动协作式自动化在中国的普及。”

Integrating the globally recognized overall equipment effectiveness (OEE) industry standard, WebLytics identifies trends in real-time in the robot cell, including patterns, peaks, and disturbances in application productivity. OEE measures the percentage of manufacturing time that is truly productive – a score of 100% indicates that the collaborative application is producing only good parts, as fast as possible, and with no downtime. Leveraging these OEE measures, WebLytics can determine whether the manufacturing process is running at optimal speed and can monitor and analyze the quality of application cycles –key insights for manufacturers of all sizes.

WebLytics集成了全球公认的设备综合效率(OEE)行业测试标准,可实时识别机器人单元的动态趋势,包括应用产能的模式、峰值和干扰。OEE标准测量真正有效的生产时间的百分比——如过测量数据为100%,则表明该协作式应用在没有停机的情况下,以最快的速度生产的每一个零件都是合格的。利用OEE测量工具,WebLytics可以确定制造流程是否在以最优化的速度运行,并可以监控和分析应用周期的质量,这对任何规模的制造商而言都是极为关键。

WebLytics can report on utilization of the robot arm and OnRobot tools such as grippers, vision cameras, and sensors, as well as the number of safety stops initiated, and the number of grip cycles performed while an application is running.

WebLytics可以报告机械臂及OnRobot工具(如夹持器、视觉摄像机和传感器)的使用情况、安全停机次数以及应用运行过程中所完成的抓取循环次数。

When changes are made to a robot cell, such as adjusting the speed of a robot or the settings on a gripper, WebLytics can also automatically report on the impact of those changes on application performance.

机器人单元如被改动,例如对机器人速度或夹持器设置进行了调整,WebLytics还可以自动报告这些改动对应用性能的影响。

If anomalies occur in the collaborative application after deployment, WebLytics enables users to analyze the data collected directly from the robot(s) and tools and report on its findings using customizable dashboards.

如果协作式应用在部署后出现异常,WebLytics能让用户直接分析从机器人和工具中收集的数据,并利用可自定义的数据面板报告其结果。

Laszlo Papp, Product Manager & Sales Engineer at Wamatec Hungary Kft., tested WebLytics on machine tending, pick & place, and palletizing applications:

“In this fast-paced world, time is everything. When cycle time is really important, WebLytics helps you identify the small mistakes that cause time wastage,” he said. “WebLytics can also save a lot of time for yourself and for your production line by making it easy to schedule all maintenance and product changes. My favorite function was the dashboard. I really liked how WebLytics allowed me to monitor all my applications, my cobots/robots, and my end-of-arm-tools using one platform that provides real time monitoring, data collection and line charting. WebLytics makes optimizing all applications much easier than before.”

匈牙利Wamatec 公司的产品经理兼销售工程师 Laszlo Papp 在机床管理、取放和码垛应用中测试了 WebLytics:

“在这个时间就是一切的快节奏的行业中,周期时间非常重要,WebLytics 可以帮助识别浪费时间的因素,”Laszlo说道, “WebLytics 还可协助我们轻松安排所有的维护和产品变更,为生产节省大量时间。数据面板是我最为欣赏的功能,仅依靠一个平台,即可监控所有应用程序、协作机器人/机器人以及末端工具的运行情况,提供实时监控、数据收集和线性图表。WebLytics 使所有应用程序的优化都变得更加容易。”

WebLytics retains the ease-of-use, affordability, application focus and accessibility that defines every OnRobot product. Compatible with all leading collaborative robot and lightweight industrial robot arms and with all OnRobot tools, WebLytics is readily expandable, futureproofing it as new robots and tools become available. Access to WebLytics’ is provided through a secure, intuitive browser-based user interface, that displays OEE measures and user-defined KPIs through customizable dashboards that provide an immediate and transparent view into real-time and historical application performance.

WebLytics拥有OnRobot产品一贯的特性:易于使用、经济、以应用为中心和易于存取的特色。WebLytics与所有领先的协作式机器人、轻量级工业机械臂以及OnRobot工具兼容,并且易于扩展,即使新型机器人和工具不断出现,WebLytics也能适应未来发展。用户可通过安全、直观、基于浏览器的用户界面访问WebLytics。这一界面拥有可自定义的数据面板,清晰呈现实时和历史性能数据,以显示OEE测量结果和用户设定的KPI。

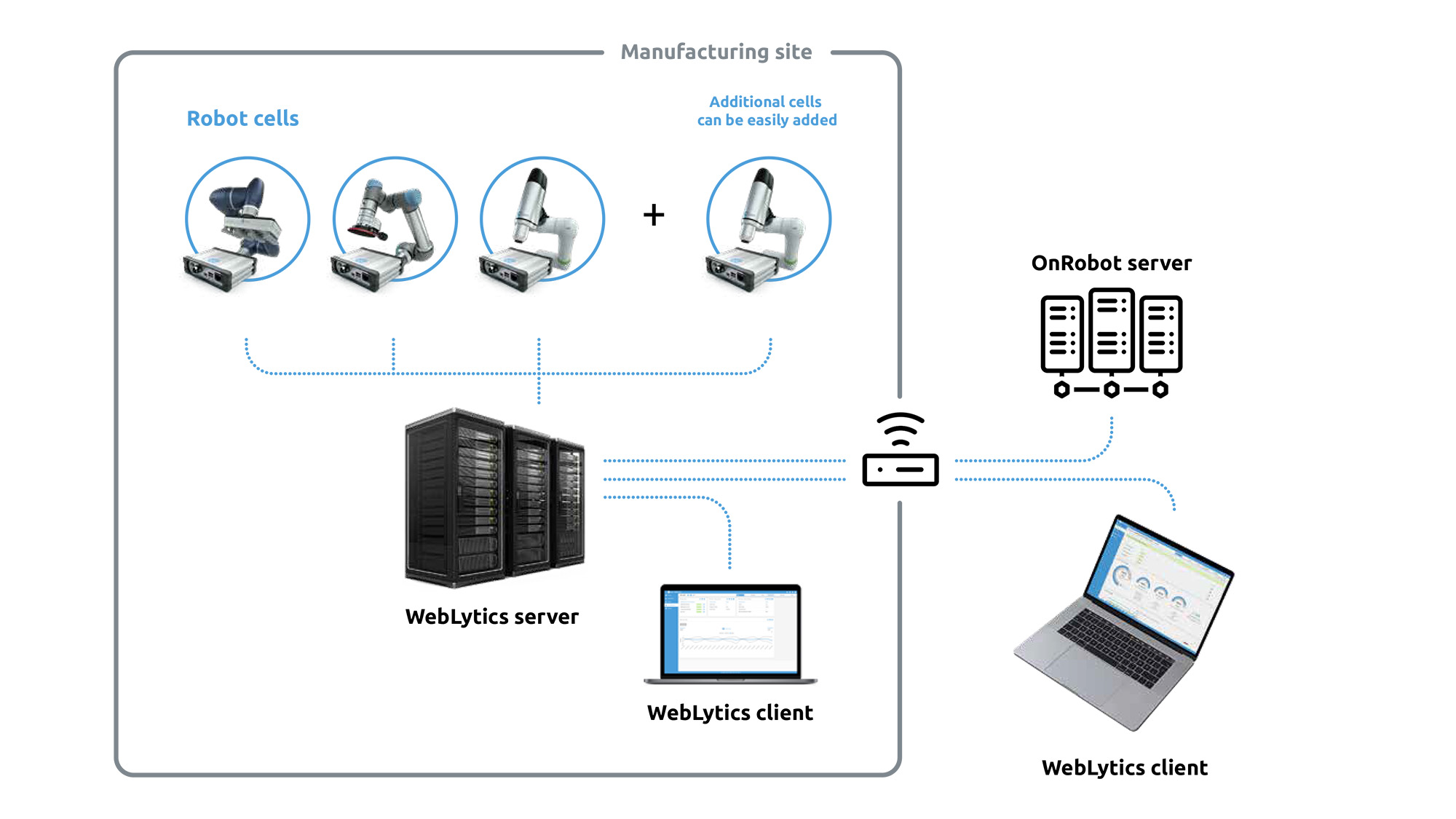

The WebLytics server can be deployed on a shop floor’s local network or added to a virtual network that connects to the robot cell. Collected data is stored locally on the WebLytics server. Meanwhile, WebLytics’ built-in web server is always accessible from the shop floor network or from anywhere in the world via secure HTTPS connection.

WebLytics服务器可以部署在生产区域的本地网络,也可添加至连接机器人单元的虚拟网络。收集的数据存储在本地WebLytics服务器。同时,无论是从生产区域的网络,还是从世界任何地方,始终可以通过安全的HTTPS连接访问WebLytics内置网络服务器。

WebLytics is not just a powerful tool for end users; it also creates new revenue opportunities for system integrators, by providing the software required to offer their customers data-backed custom service agreements and engineering services for cell optimization.

WebLytics不仅是终端用户的强大工具,也能为系统集成商创造新的收入增长机遇,因为WebLytics可以为他们客户提供数据支持的定制服务协议和单元优化的工程服务。

“WebLytics is the perfect addition to our existing product lines and a natural progression of the OnRobot tradition of making advanced tools and technologies — in this case remote monitoring, device diagnostics and data analytics — affordable and accessible to companies of all sizes,” says Iversen.

“WebLytics是对我们现有产品线的完美补充,其所具备的远程监控、设备诊断和数据分析工具及技术,也是OnRobot致力为各种规模的企业提供经济易用的先进工具和技术的传统体现。” Iversen表示。

WebLytics is available worldwide via subscription from November 11, 2021. OnRobot is participating at the upcoming 23rd CIIF event happening from 1 – 5 December at National Exhibition and Convention Centre (Shanghai). Do come join us and learn more about Weblytics and other innovation OnRobot solution for collaborative automation.

即日起,WebLytics可在全球范围内接受订购。同时,OnRobot即将参展于2021年12月1日至5日在上海国家会展中心举行的第23届中国国际工业博览会。欢迎莅临OnRobot展位8.1H E165了解关于WebLytics以及OnRobot其它协作式自动化创新解决方案的更多信息。

About OnRobot

The OnRobot product range features a wide assortment of tools and software for collaborative applications, including electric, vacuum and magnetic grippers, the award-winning Gecko gripping technology, force/torque sensors, a 2.5D vision system, screwdriver, sander kits and tool changers. Supported by the free, Learn OnRobot e-learning platform, OnRobot makes it easy to deploy collaborative automation on tasks such as packaging, quality control, materials handling, machine tending, assembly, and surface finishing regardless of skill level or previous robotics experience. Headquartered in Odense, Denmark, OnRobot also has offices in Dallas, Soest (Germany), Barcelona, Warsaw, Shanghai, Tokyo, Seoul, Singapore and Budapest.

关于 OnRobot

OnRobot产品系列为协作应用提供了广泛的工具解决方案,包括电动夹持器、真空和磁性夹持器、屡获殊荣的壁虎夹持器、轴力/扭矩传感器、2.5D视觉系统、螺丝紧固工具、砂光套件以及工具快换装置。在免费的Learn OnRobot电子学习平台的支持下,OnRobot能使用户在实施包装、质量控制、材料处理、机械维护、组装和表面处理等任务时轻松部署协作式自动化,无需考虑技能水平或在机器人领域的经验。OnRobot总部设在丹麦欧登塞,现已在美国达拉斯、德国索斯特、西班牙巴塞罗那、波兰华沙、中国上海、日本东京、韩国首尔、新加坡以及匈牙利布达佩斯设立办事处。

媒体垂询

奥美集团

Xuan Liang

xuan.liang@ogilvy.com